Separation and Conveying are two important groups of equipment, which are combined and cooperate with each other in many different industries. As the leading separation professional, GN has both the equipment for separation and for conveying.

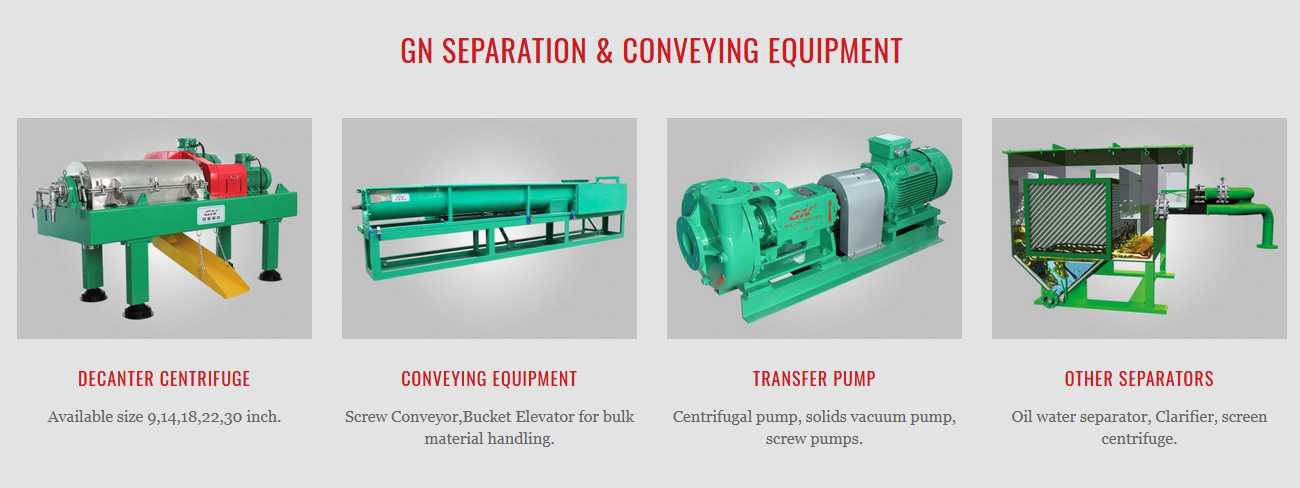

All industrial products or waste need to be well separated before put into market or before safely discharged, some are for better quality, some are for environmental protection. but the ways for separation and the conveying before and after separation are no much different. An efficient physical separation solution helps to reduce cost for the contractor. GN Separation & Conveying has following equipment for integrating a complete separation system:

1. GN has full range sized decanting centrifuges of 9 inch diameter bowl, 14 inch diameter bowl, 22 inch diameter bowl and even larger one, up to 30 inch. Also the separation of oil and water is quite important. For this application, GN has IPC, oil and water separator and disc stac to separate all three phases, oil, water and solids.

2. GN Conveying equipment: conveying equipment are mostly pumps and conveyors. Most of material to be transported are mixtures, some of higher solids content, while some are lower as mud. Based on the destination for the material to be conveyed to, and based on the largest particle size inside material, and also the characters of the next step equipment, the conveying equipment are different. GN has U type screw conveyor, belt conveyor, screw pumps, centrifugal pumps and vacuum pumps for different applications.

In all, above mentioned equipment, no matter for separation or for conveying, are widely used for industries as environment protection, food industry, beverage industry, chemical industry and mining.